Calmari® heat exchanger transfers excess heat from dryers to where it is needed

Utilizing waste heat from dryers is very profitable.

50% lower need for purchased energy

Calmari heat exchanger cuts the need for purchased energy down to half.

50% less CO2 emissions

As the need for purchased energy is reduced, so will the CO2 emissions.

25% shorter drying time

Preheating makes the drying process more efficient. Get more production capacity with a shorter lead time.

More uniform drying result

The temperature of the incoming air is constant throughout the year, therefore the drying process is more stable.

Better end-result with less waste

More uniform and more efficient drying process with half the need for purchased energy.

The drying process uses a lot of energy.

For example, a significant amount of energy is used in drying at laundries.

Usually, all the heat generated in dryers is blown out while fresh air is brought in from outdoors. A lot of energy is wasted which brings unnecessary extra costs.

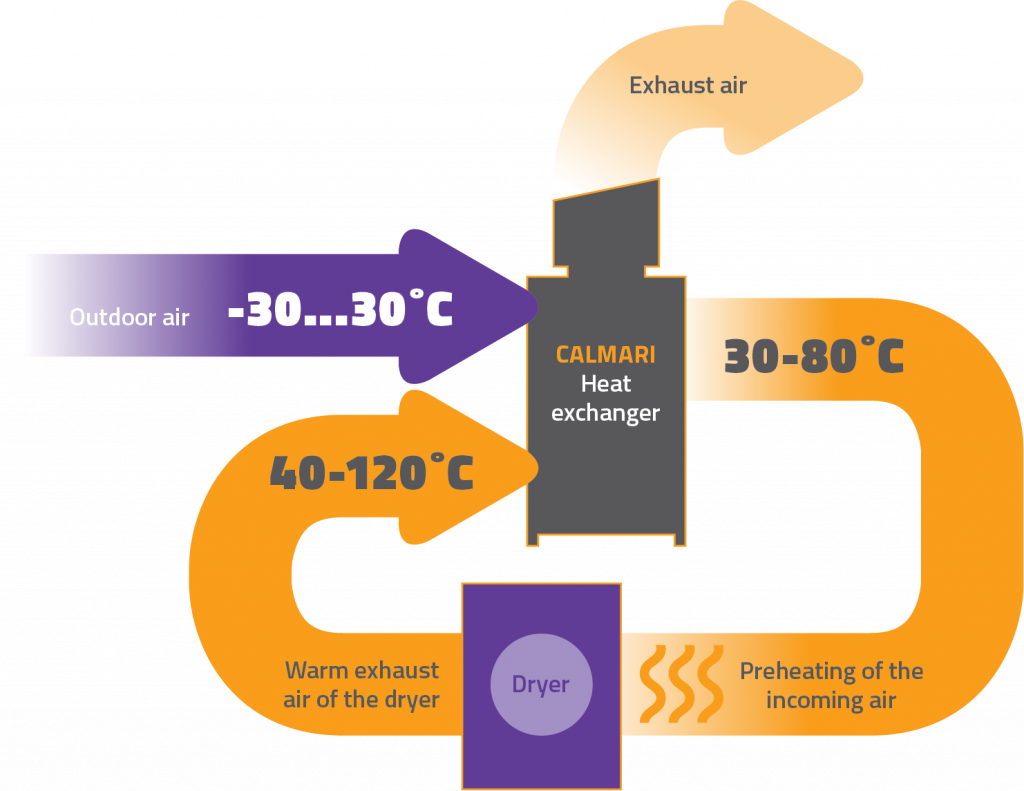

Principle

Calefa offers the Calmari heat exchanger as a total solution and turnkey delivery.

The surplus energy from the dryers is recovered from exhaust air and transferred to heat the incoming air.

Calmari can be installed e.g. on the roof, where it does not take room from the production, nor does it disturb the normal operation of the dryer. Calmari is applicable to the heat recovery of both gas- and steam-operated dryers.

Waste heat from a dryer is recycled with the patented Calmari heat exchanger.

Laundries, sand drying, etc.

Could Calmari be the right solution for you?

Ask for an assessment of which solution is the best for you.

Sami Rahkola

+358 50 550 6543

Our email addresses are

firstname.lastname@calefa.fi

Calmari heat exchangers on the roof of a laundry.